“Thermal cameras, also known as infrared cameras or thermal imagers, are devices that allow the detection and visualization of temperature differences on surfaces. They are widely used in industry for various applications., including inspection and maintenance of Steam Tracing systems.”

Application in Steam Trace

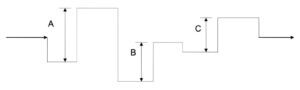

- Detecting Irregular Heating Problems: Thermal cameras are used to detect areas with irregular heating problems in Steam Trace systems. This includes identifying abnormal hot or cold spots, which may indicate system failures, such as areas with excess condensation (leading to a vapor trace line becoming flooded) or compromised pocket depth (understood as the vertical distance measured between successive low and high points in a vapor trace, flow direction, see image below).

- Predictive Maintenance: Predictive maintenance is a proactive approach to maintaining Steam Trace systems. Thermal cameras allow you to identify potential problems before they cause significant failures, saving time and resources.

- Performance Check: Thermal imaging cameras are used to verify the performance of the Steam Trace system under operating conditions. They can help confirm that heating is occurring evenly throughout the piping and that there are no areas of freezing.

- Locating Leaks and Insulation Problems: Thermal cameras can be used to locate vapor leaks or thermal insulation problems in Steam Trace systems. They identify temperature variations that may indicate the presence of leaks or areas of damaged insulation.

- Installation Inspection: During Steam Trace installation, thermal cameras can be used to verify installation accuracy, ensuring the system is working as expected from the start.

Benefits of Thermographic Cameras in Steam Trace

– Speed and Efficiency: Thermal cameras allow you to inspect large areas quickly, saving time in troubleshooting.

– Safety: Allow operators to perform remote inspections, reducing the risk of exposure to hazardous environments.

– Resource Economy: Early problem detection can prevent unplanned downtime and reduce repair costs.

– Precision: The thermal images provided by thermal cameras are highly accurate in identifying temperature variations.

In summary, thermal imaging cameras play a crucial role in inspection, maintenance and monitoring of Steam Trace systems. They help to ensure the operational efficiency, the security and reliability of these systems, identifying potential problems before they cause significant damage.

Na tayga, Our highly trained and qualified technicians utilize state-of-the-art thermal imaging cameras as part of our inspection and maintenance procedures

Meet Tayga

We invite you to discover the Tayga Heating Solutions and discover how our expertise, cutting-edge technology and commitment to quality can benefit your industry. If you are looking for reliable heating and thermal insulation solutions, Tayga is the right choice.

We are ready to work side by side with you, understanding your needs and offering personalized solutions that drive your success. Contact us today and discover how our heating and insulation solutions can make a difference in your industry.

We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

It will be a pleasure to get to know your industry and help with our customized energy efficiency solutions!

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):