Heating storage tanks and reactors in adverse temperature conditions is a common challenge faced by industrial sectors. In addition to keeping operations running without interruptions, is important ensure that product quality is maintained. That's where the steam tracing and electrical tracing solutions.

Both the System Steam Tracing and Electric Tracing Systems are ideal solutions to guarantee the heating of industrial equipment such as storage tanks and reactors. Each of these systems has different applications and different benefits.. Let's analyze each of them below.

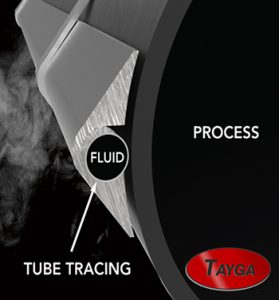

Steam Trace

This type of solution is known to be efficient and reliable.. The steam is conveyed through a pipe to storage tanks or reactors, ensuring continuous and uniform heating. Besides that, steam can also be used to maintain a stable temperature inside tanks, avoiding condensation and maintaining product quality.

Another benefit of steam tracing is its versatility., as it can be used in a wide range of industrial applications, including oil, gas, chemical, pharmaceutical, food and much more.

In addition to conventional steam tracing, there is the High Performance Steam Dash (MHT), solution developed by Tayga to significantly increase heat transfer from heat piping to process piping, in order to obtain higher temperatures. A system 100% designed to ensure less maintenance and better use of steam energy, which results in significantly increased efficiency.

Electric Trace

Another efficient solution for heating tanks and reactors. This solution involves installing electrical resistance on the walls of tanks or reactors., allowing temperature to be controlled precisely and evenly. Besides that, The electric trace is a very versatile solution and can be used in various types of tanks, reactors and auxiliary equipment.

Another benefit of the electrical trace is that it is safe and easy to install, ensuring shorter installation time and low maintenance costs.

What is the best solution?

Both solutions, Steam Trace and Electric Trace are highly efficient for heating tanks and reactors, as they allow the temperature to be controlled precisely, ensuring that product quality is maintained. These solutions also ensure the continuity of operations, avoiding interruptions and loss of time and resources.

The choice between Steam Tracing and Electric Tracing depends on several factors, including heating needs, operating conditions and safety. It is important to consider the advantages and disadvantages of each system before deciding which is best for your applications..

For this choice, It is essential to have the support of a specialized company and Tayga is a leading company in designing and implementing Steam Tracing and Electric Tracing Systems in industries. We are able to provide Turn Key solutions, through a personalized approach to meet our customers' heating needs. We work from project evaluation to system installation and maintenance.

To understand how we can help your industry and learn about our projects, contact through the site (click here), fur e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

To understand how we can help your industry and learn about our projects, contact through the site (click here), fur e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

It would be a pleasure to meet your company and help with our customized energy efficiency solutions!

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):