Learn how to avoid unexpected failures and stops with an efficient preventive and predictive maintenance plan for thermal trace systems. Discover best practices to ensure safety, efficiency and prolong the life of industrial heating systems.

The reliability of thermal trace systems, whether electric or steam, depends directly on an efficient maintenance plan. Without a well -defined strategy, Failures can occur, Impacting security directly, energy efficiency and operational continuity. Na tayga, We reinforce the importance of preventive and predictive maintenance to maximize the life of systems, minimize repair costs and ensure that the temperature of industrial processes is kept without interruption.

In this article, We explore best practices to avoid unexpected flaws and stops, ensuring maximum efficiency of thermal trace systems.

The importance of maintenance in thermal trace systems

Electric and steam systems are responsible for thermal control in critical industrial processes, ensuring that fluids and gases remain at the ideal temperature. Without proper maintenance, Problems such as damaged thermal insulation, overheating, clogging of pipes and cable failures can compromise the operation, resulting in unexpected stoppages and high repair costs.

Preventive and predictive maintenance allows:

- Reduction of operating costs: Avoid energy waste and expensive emergency repairs.

- Increased operational safety: Prevents failures that may result in accidents or damage to equipment.

- Longer system life: Minimizes premature wear, increasing the longevity of the components.

- Prevents unplanned stops: Guarantees the continuity of production processes without unexpected interruptions.

Difference between preventive and predictive maintenance

Although both are essential, preventive and predictive maintenance have different approaches:

Preventive maintenance

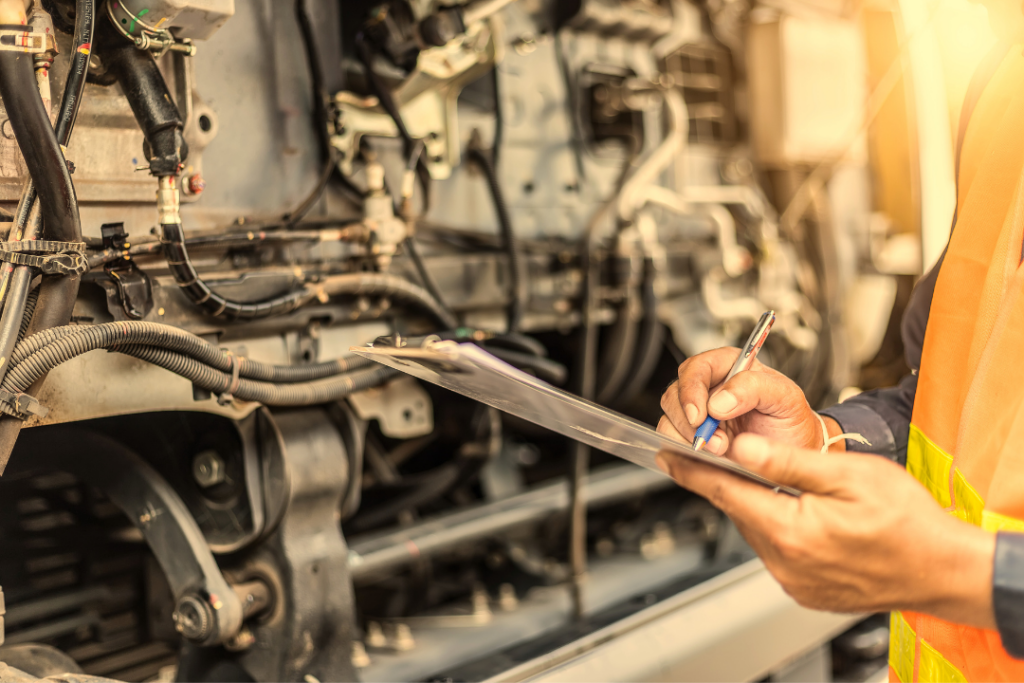

Preventive maintenance is based on inspections and scheduled actions to avoid failures before they occur. Involves replacing worn parts, periodic inspections and tests to ensure that the system operates within the ideal parameters.

Main activities:

- Visual inspection of cables and pipes.

- Electrical Tests in Electrical Traces (Megger, insulation resistance).

- Verification of thermal insulation and mechanical integrity.

- Cleaning and clearing steam lines.

- Adjustment of thermostats and temperature controllers.

Predictive Maintenance

Predictive maintenance, on the other hand, uses continuous monitoring and advanced techniques to detect failure signals before they become critical. Sensors and thermal analyzes are used to predict problems and act preventively.

Main activities:

- Cable and pipe temperature monitoring.

- Thermography use to identify hot points or insulation failures.

- Vapor pressure and flow measurement to avoid blockages.

- Analysis of the electrical resistance of the cables to predict degradation.

Main practices for maintaining electric trace systems

Electric trace systems require attention to specific details to ensure their continuous performance. Some of the main practices include:

- Periodic inspections: Visual and electrical verification of heating cables, connections and thermostats.

- Continuity and isolation tests: Use of equipment as a megger to measure insulation resistance and detect damaged cables.

- Regular thermal analysis: Application of thermography to identify heat distribution failures and imminent failure points.

- Programmed Component Replacement: Preventive Cable Exchange, connectors and sensors before they have failures.

- Review of thermal insulation: Guarantee that isolation is intact to avoid unnecessary thermal losses.

Main practices for maintaining steam trace systems

Steam trace systems require detailed inspections to avoid problems such as leaks and clogging. To ensure maximum performance, It is recommended:

- Verification of vapor purges: Regular maintenance and testing to avoid condensate accumulation, ensuring system efficiency.

- Steam line inspection: Identification and repair of leaks and corrosions that may compromise the operation.

- Pressure and Flow Monitoring: Periodic adjustments to avoid loss of efficiency in thermal transfer.

- Steam Quality Analysis: Prevents the drag of moisture and impurities, ensuring that the steam provides as much heat as possible.

- Monitoring of thermal expansion: Prevention of tubing deformations due to temperature variations.

Good practices to avoid inefficiencies and failures

Tayga recommends a structured maintenance plan, adapted to each type of system and the specific needs of each client. Some good practices include:

- Prepare a maintenance plan: Define inspection schedules and regular tests.

- Train technical teams: Enable maintenance professionals to ensure correct identification and correction of failures.

- Use Monitoring Equipment: Sensor application, thermography and electrical tests for continuous performance analysis.

- Perform periodic analyzes of efficiency: Evaluation of energy consumption and thermal performance to identify possible optimizations.

Tayga's commitment to intelligent maintenance

Na tayga, We understand that an efficient thermal trace system is not just about the installation, but also to continuous technical support. That is why, We offer complete solutions that include:

- Specialized Engineering: Personalized projects focused on durability and efficiency.

- Monitoring and Support: Technical inspections and continuous monitoring of system performance.

- High Performance Solutions: Electric and vapor trait designed to minimize corrective maintenance and reduce operating costs.

DDiscover how Tayga heating solutions can transform your industrial operations.

Get in touch today to learn more about our services and how we can help you achieve excellence on your next project.

We are available through do site (click here) or by e-mail contato@taygahs.com or at phone and Whatsapp (21) 9.8819-3687.

We also recommend reading our materials on the heating and insulation systems implemented by Tayga (just click and you will be redirected):